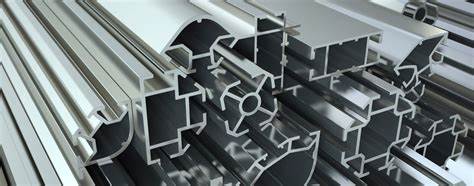

Aluminium Extrusions

Welcome we are professionals in aluminium extrusions, We can command your project from Start to Finish, carrying out every process assuring that you have the strongest quality extrusion and fabrication solutions possible every time. We can provide a standard and bespoke aluminium profiles which can be from a variety as little as 50kg for prototyping to batch lengths over 40 tonnes, All of our aluminium extrusions suppliers are all ISO:9001 accredited. This pushes us to keep high standards throughout our supply chain.

What is aluminium extrusions:

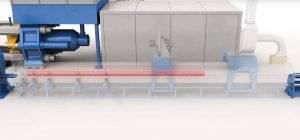

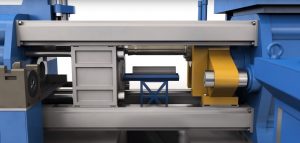

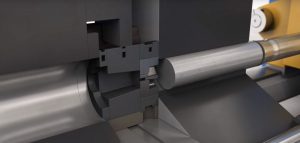

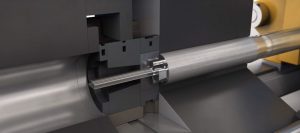

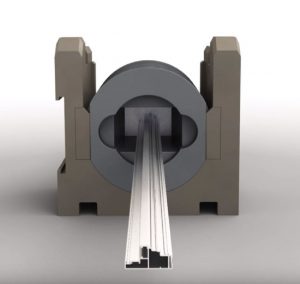

It generally applies the term extrusion to both the process and the product obtained when a hot cylindrical billet of aluminium is forced through a shaped die. We can use the resulting section in long lengths or cut into small parts for constructions, cars, or components. Also, extrusions are used for the starting stock for drawn rod, cold extruded and forged products. While the majority of the many hundreds of extrusion presses used throughout the world are covered by the simple description given above, we should mention it that some presses accommodate rectangular shaped billets for the purpose of making extrusions with large section sizes. Other presses are designed to push the die into the billet. This latter modification is usually termed “indirect” extrusion.

Aluminium extrusion applications:

Whether you’re looking for Aluminium profiles for lighting, display, electronic or automotive applications whatever the size, shape or quantity we’re certain we can help you.

Using extruded aluminium is limited only by imagination. There is in the market today an assortment of aluminium extrusion is made and customised according to the specific requirements of the customers.

We use aluminium for a wide range of applications all around us – at work on your desk, office screening, whiteboards, heat syncs in your laptop. In your car – treadplate, grills, interior trim. At home – in your kitchen appliances, bathroom tile trims, etc.

Worldwide, Building and Construction industry is the major consumer of aluminium extrusions followed by the industrial and the transportation segments. The high conductivity of heat and electricity makes this downstream product apt for nuclear reactors as well!

Whether you’re considering for aluminium profiles for lighting, display, electronic or automotive applications whatever the size, shape or quantity we’re sure we can help you.

Using extruded aluminium is limited only by imagination. There is in the market today an assortment of aluminium extrusion is made and customised according to the individual requirements of the customers.

We use aluminium for a broad range of applications all around us – at work on your desk, office screening, whiteboards, heat syncs in your laptop. In your car – treadplate, grills, interior trim. At home – in your kitchen appliances, bathroom tile trims, etc.

Worldwide, Building and Construction industry is the major consumer of aluminium extrusions followed by the industrial and the transportation segments. The high conductivity of heat and electricity makes this downstream product apt for nuclear reactors as well!

Worldwide, Building and Construction industry is the major consumer of aluminium extrusions followed by the industrial and the transportation segments. The high conductivity of heat and electricity makes this downstream product apt for nuclear reactors as well!

Can we make bespoke aluminium extrusion from our consumer drawings?

There are 50% of the extruded aluminium products made from supplied drawing …Whatever your inquiry may be, our caring and friendly service team are more than happy to help. You can either send us a brief message or a detailed inquiry with drawings or sketches. We will get in contact with you as soon as we can to discuss your needs better.

Each aluminium processing firm in the world has to deal with the risks of varying aluminium prices and as a result the prices for intermediate goods and the prices of finished known products. Through experience we have learned that not only supply and demand is an important part for the historical aluminium prices, but above expectations and sentiments in the commercial sector, the price of aluminium determination.

The risks of fluctuations of aluminium:

These variations have a direct impact on the profit margins, the amount of the stock, but also behaviour of clients who bought the aluminium suddenly do want to diminish or delay the order. Companies seek control of these risks by making good agreements with both clients and suppliers of aluminium.

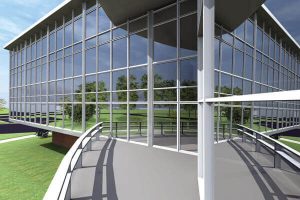

Aluminium Extrusion In Construction:

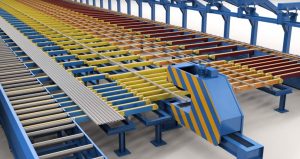

The biggest consumer of Aluminium Extrusions or extruded aluminium products is the building and construction industry. Followed globally by the industrial and transportation sectors.

With the construction and building sectors, Aluminium Extrusions are steadily replacing traditional iron, concrete and wooden components. From aluminium railings, staircases and panels to aluminium framing components.

Other applications within this type of industry range from prefabricated windows and doors, to curtain walling systems, decking and canopies. Atrium’s and arches, geodesic domes and even bridge decks.

The formwork sector is also one that has rapidly grown to use extruded aluminium products for steel frames, brackets and connecting components. Aluminium structural components are receptive to top-grade architectural coatings which help in further value-addition.

The uses for Aluminium Extrusions in construction are endless, offering much more than just weight saving attributes. The end product can be manufactured to incorporate additional features in fixings, channels, and interlocking systems that preclude the need for additional parts.

Aluminium trading:

In basic industry, it is already customary to price risk management by trading the future market for aluminium, the London Metal Exchange (LME). We list the world prices of aluminium on the London Metal Exchange (LME) and form the basis for price calculations of many aluminium processing enterprises. The LME aluminium gives the price in U.S. dollars per 1,000 kg. The ‘settlement price’ is the official cash sale and serves as a basis for contracts.

Extruded Aluminium in Space

Extruded aluminium tubing is playing an integral part in the most complex international scientific venture in history. Boeing Company engineers designed an intricate aluminium truss structure to house the International Space Station (ISS) currently weighing in at over 400,000 pounds, measuring 146 feet long, 240 feet wide and 90 feet high. Aluminium extrusions provide the mechanical properties and surface finish needed for this mission-critical application.

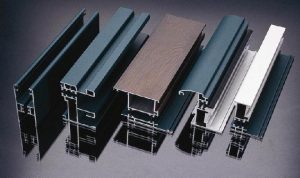

Standard Profiles:

Bespoke Profiles:

Aluminium facts

- Close to 70% of all aluminium drinks cans are recycled globally, making the aluminium drink can the most recycled drinks container on the planet.

- Anything made of aluminium can be recycled repeatedly – not only cans, but aluminium foil, food trays, window frames, automotive components. All can be melted down and used to make the same (or other) products again.

- Every minute of every day, an average of 113,200 aluminium cans are recycled.

- Used aluminium drink cans can be recycled and back on supermarket shelves as new drink cans in as little as 60 days.

- But if an aluminium can goes to landfill, it will stay there for 500 years before it oxidises.

- If all aluminium cans were recycled in the UK, we would need 14 million fewer dustbins. Tidy!

- Around 5.9 billion aluminium drinks cans are recycled in the UK every year. That’s enough to circle the world almost 18 times if laid end to end.

- Recycling one tonne of aluminium saves the carbon dioxide emissions of driving nearly 27,000 miles.

- Recycling one aluminium can saves enough energy to run a television for three hours.

- Recycling aluminium takes 95% less energy than producing it from its raw materials. The recycling process also generates only 5% of the greenhouse gas emissions.

Reducing auto emissions while increasing safety

An automobile designed with 1 pound of aluminium extrusions instead of 2 pounds of steel will save 3.1 gallons of crude oil, and prevent 20 pounds of CO2 emissions over its lifetime. North American car manufacturers plan to increase the use of aluminium in cars and light trucks by over 40% from 2012 to 2025. Aluminium tailgate frames, engine mounts, roof consoles and running boards are also corrosion resistant and more resilient in crashes due to their inherent strength and flexibility.

It’s lightweight—Aluminium weighs less by volume than most other metals. In fact, it is about one-third the weight of iron, steel, copper, or brass. This makes it easier to handle and less expensive to ship.

It’s strong—Aluminium extrusions can be made as strong as needed for most applications. Cold-weather applications are particularly well-served by aluminium because, as temperatures fall, aluminium actually becomes stronger.

It’s non-corrosive—Aluminium does not rust. It’s protected by its own naturally occurring oxide film, a protection that can be further enhanced by anodising or other finishing techniques.

It conducts heat—Based on weight and overall cost, aluminium conducts heat (and cold) better than other common metals. These factors make it ideal for applications requiring heat exchanges.

It’s non-sparking—Aluminium doesn’t emit sparks. This makes it a great choice in applications that involve explosive materials or that are used in highly flammable environments.

It conducts electricity—Bulk power transmissions generally take place via aluminium because, pound-for-pound, aluminium is twice as conductive as copper.

It’s nonmagnetic—Because aluminium does not acquire a magnetic charge, it’s useful for high-voltage applications, as well as for electronics, especially where magnetic fields come into play or where sensitive magnetic devices are employed.

It’s resilient—Aluminium combines strength with flexibility and can flex under loads or spring back from the shock of impact.

It’s reflective—Highly reflective aluminium can be used to shield products or areas from light, radio waves, or infrared radiation.

It’s non-combustible—Aluminium does not burn and, even at extremely high temperatures, it does not produce toxic fumes.

It’s recyclable—Aluminium retains a high scrap value. It can be recycled indefinitely without losing any of its superior characteristics.

It accepts finishes—Aluminium can be finished with a variety of common techniques, including liquid paint, powder coatings, anodising, or electroplating.

It’s seamless—With aluminium, complex shapes can be realised in one-piece extruded sections without having to use mechanical joining methods. This makes the parts stronger and less likely to leak or loosen over time.

External Links

https://en.wikipedia.org/wiki/Extrusion

https://www.lme.com/en-GB/Metals/Non-ferrous/Aluminium#tabIndex=0