Anodising

What is Anodising?

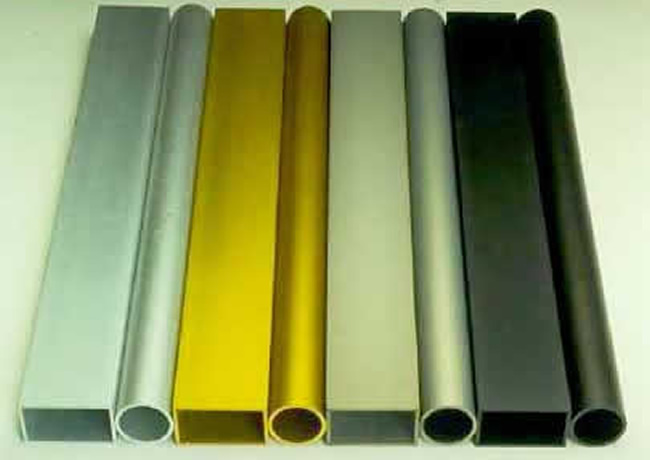

Anodising is an electrolyte process which is used to increase the thickness of the oxide coatings for metal, more specifically with Aluminium and its alloys.

Specifications & Alloys

Does anodising affect the mechanical properties of aluminium?

Mechanical properties of aluminium, such as ultimate strength and yield strength, along with percent elongation, reportedly have been tested before and after anodising without exhibiting any difference in the strength of the aluminium. Aluminium is a very soft metal and if not protected can be abraded away, whereas the anodic oxide is much harder.

Why do aluminium parts I send to be black anodised sometimes come back with a purple hue, and how can this be avoided?

The purple hue is an iridescent colour–the result of a very thin film on the surface of the black anodised part. Other iridescent colours can be produced, and can appear even on clear anodised parts, but are most evident on black anodising.

An analogy is a black asphalt road after rain. A droplet of oil causes iridescent rings that are quite apparent on black asphalt but can hardly be seen on a light-coloured concrete road. There are a number of possible causes of the film. One is sealing smut. Hot water sealing blocks the pores of the anodic coating, thus improving its weathering resistance, reducing its adsorptive properties, and sealing in any pigment. However, some sealing product forms on the outer surface of the anodic coating. This is sealing smut. It consists of very small, needle-like crystals of aluminium hydroxide. They act as a thin film that can generate iridescent colours. Anti-smut additives for sealing baths are available, which minimize the problem.

The formation of smut can be favoured by high pH. The bath chemistry should be controlled as recommended by the supplier of the sealing additive. Alternatively, the smut can be wiped off. Before the invention of anti-smut additives, people used to wipe down parts with lanolin in white spirit. This temporarily masks the smut as much as it removes it. Manual removal is time-consuming and can be hard work.

Anodising under conditions that are too aggressive can lead to iridescent effects. In particular, if the bath temperature is too high, the surface region of the porous anodic coating (the part of the coating that was first formed during anodising) can be dissolved in the acid solution to the extent that it is very much more porous. This is called a “soft” coating.

In general, anodising at over 75°F for more than 45 minutes can produce a soft coating. A simple abrasion test to detect a soft coating is described in British Standard 6161: Part 18: 1991. Also, purple iridescence has been seen with certain types of black dyed parts if the film thickness is too low or the dye bath is inadequately controlled. The advice of the supplier of the dye should be followed.

What about rack marks?

Electrical contact must be made to each part that is anodised. The more electrical current required, the bigger the electrical contact must be. The size of the contact therefore depends on the anodising process and the size of the part being anodised.

Can anodising hide scratches?

The usual rule of thumb is that if you can feel a scratch by rubbing your fingernail across the surface, you will be able to see the scratch after anodising. It is always helpful for the finisher to understand the application. It is also good for the finisher and client to agree on a viewing distance. If a part is to be viewed from 10 feet away, like a window or roofing component, then the inspection may be relatively insensitive to scratches. However, if the part is to be viewed from 24″ or closer, then even a scratch which you cannot feel may be unacceptable.

Can I weld anodised aluminium?

Parts can be welded prior to anodising. The use of 5356 welded rod is strongly recommended, though some discolouration will still occur. 4043 is the worst choice because it will turn a smutty black when anodised. Grinding away the weld before anodising will result in decreased mechanical integrity and will not solve the appearance variation problem. It is not a good idea to weld after anodising. Because most welding process require electrical conductivity the anodic coating must be ground away where the weld will be applied.

This normally results in an unsightly mess around the welding area.

Why do weld areas on some parts look different than the rest of the part? How can such anomalies be minimised?

Welds can discolour for a couple of different reasons. First, the metallurgy of the welding wire is different than that of the alloy being welded. Since the finish produced in the anodising process is somewhat dependent on the metallurgy, the metallurgical difference will show up as a shade difference.

Secondly, during the welding process a significant amount of heat is built up around the weld. This heat build-up actually changes the temper of the aluminium immediately surrounding the weld bead. Since a temper change is really a metallurgical change, again this shows up after anodising as a colour difference. These areas are commonly called halos or ghosts. There are a few things that can be done to minimise the colour differences.

First, excellent results may be produced by using welding wire alloy 5356. This alloy reportedly produces the best colour or shade match when used to weld 6xxx series alloys. The second problem, concerning halos or ghosts, is a little more difficult to solve. Try using as little heat as possible to accomplish the job. This can be something of an art and is dependent on the individual doing the work.

Another possibility is to put the aluminium that is being welded in contact with a chill block that will draw the heat away from the working area. One other note: Some people grind the weld bead smooth and mechanically finish the weld area in an attempt to avoid the colour difference. This practice, however, will not help hide the discolouration.