CNC Machining Process

Nevilles have 12 CNC Machining Centres ranging from 5 Axis, 4 Axis and 3-Axis which are made by 4 different manufacturers.

This gives us the unique opportunity to capitalise on each machines strengths and weaknesses with the appropriate profile being allocated to the right machine driving down cycle times helping reducing costs for the customers.

The longest CNC machine is 8,000mm, however, we have the capability to machine parts from 15,000mm down to to 50mm .

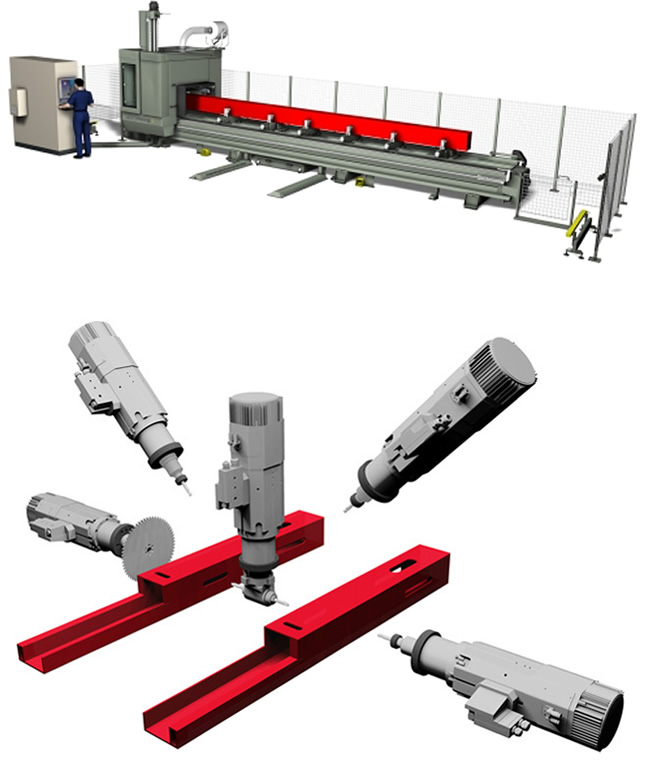

The machining centres are fitted with a mobile gantry structure, designed for milling, drilling, thread-cutting and slotting operations at any angle from 0° to 180°.

The machines have automatic tool change capabilities up to 20 tools which are placed in a magazine general located on the mobile gantry. The machine can be used in dynamic double mode which allows minimising machine downtimes as it is possible to carry out the work piece change operations (loading/unloading) and automatic positioning of the vices in concurrent operation time.

It is also possible to load, then machine, work pieces with different codes and machining operations between the two work areas.