Aluminium Section Bending

To bend the aluminium sections, the process is near identical. It has mild steel sections;The difference is that Aluminium extrusions requires higher levels of accuracy and control because of the different properties of the metals. When bending aluminium, it has a tendency to work-harden and crack if we do not use the correct methods. Aluminium comes in several grades and tempers. The most commonly used aluminium alloy is 6063 T6. 6063 T6 has good formability, weldability and corrosion resistance. They often use 6082 for architectural applications. This grade is highly corrosion resistant and has good formability. At Neville Precision, we can offer 3 different methods of section bending.

Mandrel bending

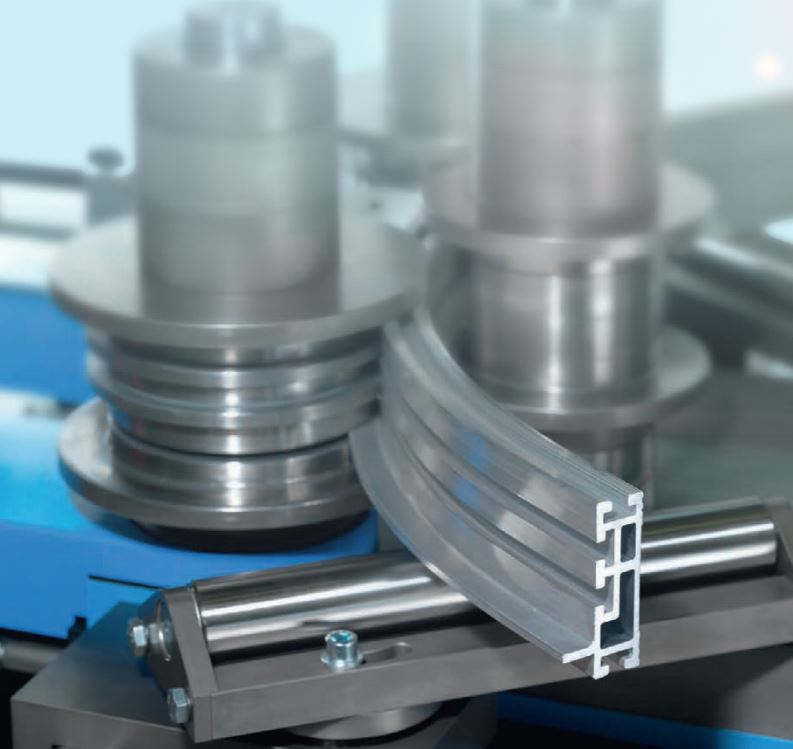

When rolling a (thin walled) profile in a small radius, there is an increased risk of tearing and straining. To prevent this, means of mandrel are used to bend the profile bending.

I need a special CNC mandrel bending machine for this technique and requires product specific equipment to limit deformation of the cross section to an absolute minimum.

Stretch bending

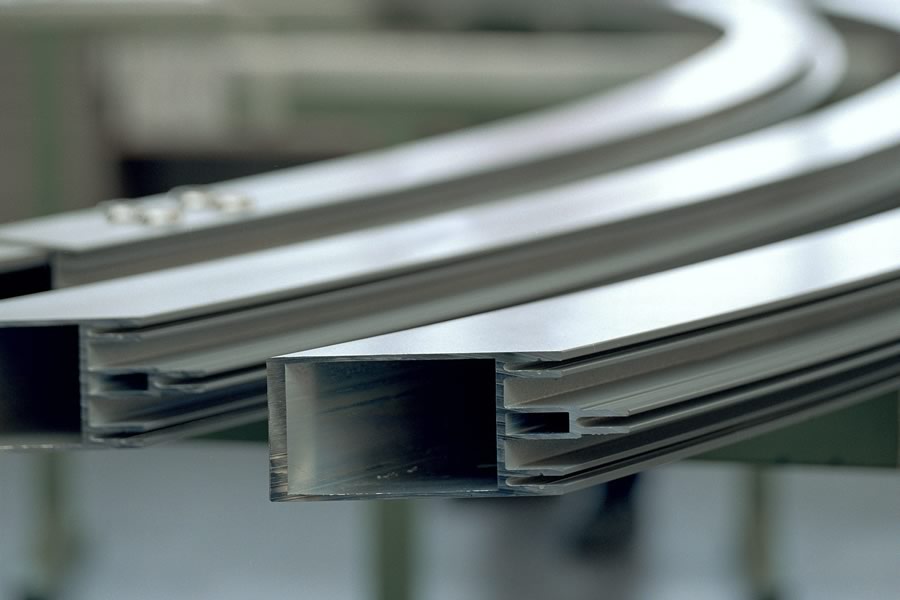

Stretch bending originated within the aviation industry, it is now also widely used for architectural, machinery, and automotive applications.

It is a very precise bending method in which the material surface remains in perfect condition and the diameter is distorted minimally. It is ideal, for example, for aluminium facade profiles, tent profiles and aerofoils, where the visual aspect of the application is very important.

We use a special stretch bending machine for this bending process. This firmly clamps the profile at both ends, tensions these and then pulls them back, around a mould.

In contrast to rolling, the profile does not come into contact with the machine.

NEW FOR 2021 Neville Purchase 80MRE Aluminium Profile Bender